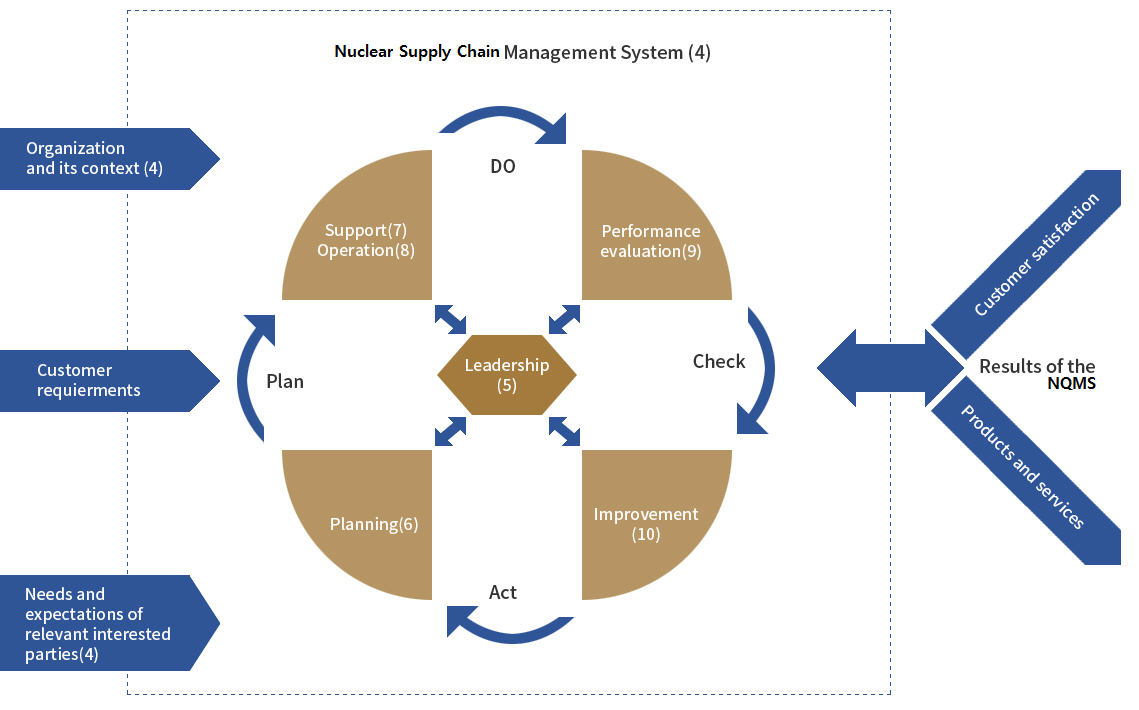

The Quality Management System for the Nuclear Supply Chain is a structured system that includes methodologies and procedures to effectively manage the quality within the nuclear supply chain, particularly for nuclear power plants, nuclear facilities, and nuclear-based manufacturers.

This system is built upon the ISO 9001 quality management framework with added requirements for "Nuclear Safety Culture" and "Nuclear Quality Assurance Program" to ensure the reliability and operational effectiveness of suppliers providing products and services critical to nuclear safety (ITNS).

* Nuclear Safety: Protecting workers, the public, and the environment from excessive radiation risks through the attainment of proper operational conditions, accident prevention, and mitigation of accident consequences.

* ITNS (Important to Nuclear Safety): Products, services, items, or activities whose failure could result in excessive radiation exposure to individuals or the environment.

The key requirements of 19443 are as follows

1. Nuclear Safety Culture: Refers to the collective characteristics and attitudes of organizations and individuals that prioritize nuclear safety. It defines nuclear safety as a core value, ensuring that regulations are followed and decision-making and tasks are conducted with nuclear safety as a priority.

2. Determining ITNS Items and Services: Organizations are required to identify the characteristics of products, services, or activities that could expose people or the environment to excessive radiation in case of failure, and carry out preventive measures.

3. Graded Approach: This method ensures that quality control, documentation, monitoring, and measurement requirements are appropriate to the importance of nuclear safety. Organizations must classify and manage these requirements accordingly.

4. Use of Commercial-Grade Items: Items or activities not specifically designed or manufactured according to nuclear-specific requirements must be properly verified for use to ensure nuclear safety is maintained.

5. Counterfeit, Fraudulent, or Suspect (CFS) Items: Any CFS items discovered must be managed as non-conformities, and relevant parties, including customers, must be notified without delay.

1. Improved Quality: Implementing a nuclear supply chain quality management system enhances the quality of products, services, and processes. Refined quality control procedures help reduce product defects and improve customer satisfaction.

2. Enhanced Safety and Reliability: The system strengthens the nuclear safety culture and boosts the reliability of nuclear power plants. By adhering to safety requirements and effectively managing risks, it helps reduce the likelihood of accidents and disasters.

3. Prevention of Counterfeit, Fraudulent, or Suspect (CFS) Items: By building a nuclear supply chain quality management system, organizations can ensure transparency regarding product origin and manufacturer details, and strengthen supplier verification and monitoring to prevent suspicious items from entering the supply chain. This helps maintain product safety and reliability, offering consumers safe and trustworthy products.

4. Strengthened Compliance with Regulations: The nuclear industry is highly regulated, with strict safety and quality requirements. A nuclear supply chain quality management system enhances compliance with relevant regulations and ensures that organizations are properly aligned with these rules.

5. Improved Customer Satisfaction: Higher quality leads to greater satisfaction among customers, users, and stakeholders. The safe and reliable operation of nuclear power plants helps build customer trust.

6. Fostering a Culture of Continuous Improvement: The quality management system promotes continuous improvement within the organization. By using data and feedback to improve processes and address issues, organizations can consistently enhance their capabilities and performance.

| No | Scope of Accreditation |

|---|---|

| A | Machinery and structure |

| B | Electrical equipment |

| D | Electricity generation and supply |

| E | Construction |

| F | Transportation and waste treatment |

Contact Person

kgb@icrqa.com

lee2750@icrqa.com